Brass CNC Machining Service

At Ruixi Technology, we provide precision brass CNC machining for high-quality custom parts and prototypes. Our CNC machines ensure accuracy, a great surface finish, and fast production times. Whether you need small prototypes or large production runs, we can meet your needs.

We are certified to ISO 9001:2015 and ISO 14001:2015 standards, ensuring that every brass part we manufacture meets high levels of precision and consistency. With our experience in the U.S. market, we know the importance of fast delivery, competitive pricing, and strict adherence to quality standards.

What is Brass CNC Machining?

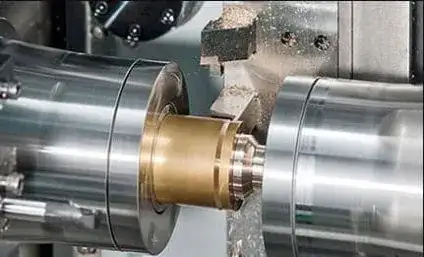

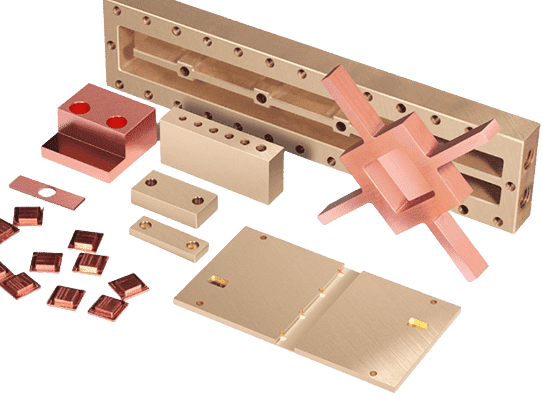

Brass CNC machining is a subtractive manufacturing process that uses computer-controlled machine tools to precisely remove material from brass workpieces. Brass, a copper-zinc alloy, is well-suited for CNC machining due to its excellent machinability, corrosion resistance, and electrical conductivity. These properties make it an ideal material for components in the automotive, electronics, plumbing, and home appliance industries.

The CNC machining process for brass involves programming computer numerical control (CNC) machines to follow precise toolpaths, removing material to create the desired shape with exceptional accuracy.

Why Choose Brass for CNC Machining?

Brass offers several advantages when it comes to CNC machining, including:

- High machinability: Brass allows for high-speed machining with minimal tool wear, reducing production costs.

- Corrosion resistance: Its natural resistance to corrosion makes brass components ideal for applications in humid or harsh environments.

- Thermal and electrical conductivity: Brass is highly conductive, second only to silver, making it a popular choice for electronic connectors and heat sinks.

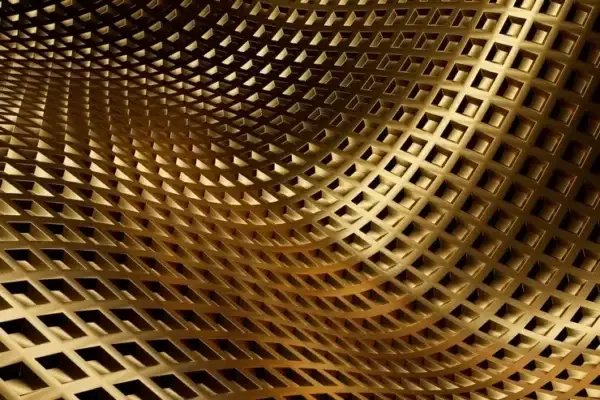

- Aesthetic appeal: Brass has a natural golden finish, perfect for decorative applications without additional surface treatments.

- Strength and durability: While not as strong as steel, brass provides a good balance of strength, ductility, and resistance to wear, especially in applications like gears, fasteners, and fittings.

For applications where material properties are a critical decision factor, our guide on comparing brass and bronze properties provides detailed insights into the differences between these similar copper alloys.

Precision CNC Machining Services

Our comprehensive CNC machining services for brass include:

- Turning: Producing cylindrical parts like shafts, bushings, and fasteners.

- Milling: Ideal for creating complex geometries and fine details in brass parts such as valves, fittings, and brackets.

- Multi-axis CNC Machining: For complex parts that require high precision and multiple machining operations in one setup, such as custom brass prototypes.

We utilize advanced CNC lathes and multi-axis milling machines to ensure precision and quality in every part we produce. For projects requiring quick turnaround, our rapid brass machining services can deliver prototype parts within 24 hours.

Common Brass Grades for CNC Machining

We work with a variety of brass grades to meet the specific needs of your project, including:

|

Grade |

Composition |

Properties |

Machinability Rating |

Typical Tolerances |

Common Applications |

|---|---|---|---|---|---|

|

C360 Brass |

61.5% Cu, 35.5% Zn, 3% Pb |

|

100% (Standard) |

±0.001“ for diameters ±0.002“ for lengths |

|

|

C260 Brass |

70% Cu, 30% Zn |

|

30% |

±0.002“ for diameters ±0.003“ for lengths |

|

|

C230 Brass (Red Brass) |

85% Cu, 15% Zn |

|

20% |

±0.002“ for diameters ±0.003“ for lengths |

|

|

C385 Brass (Architectural Bronze) |

57% Cu, 40% Zn, 3% Pb |

|

80% |

±0.0015“ for diameters ±0.0025“ for lengths |

|

Surface Finishes for Brass CNC Machined Parts

To enhance the durability and aesthetic appeal of your brass parts, we offer a variety of surface finishes, including:

- Polishing: Provides a smooth, shiny finish, ideal for decorative or high-visibility parts.

- Electroplating: Adds a layer of protection against corrosion with options like zinc, nickel, and chrome plating.

- Anodizing: Enhances corrosion resistance and adds color, commonly used in architectural and consumer products.

- Passivation: Reduces the chance of oxidation on brass parts, extending the lifespan of components in demanding environments.

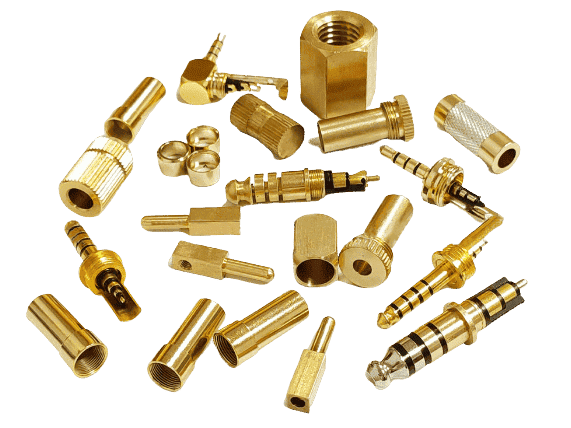

Industries We Serve

Our brass CNC machined parts are widely used across multiple industries due to their versatility and durability:

- Electronics: High-conductivity brass components like connectors and terminal blocks.

- Automotive: Durable parts such as bushings, valves, and fittings.

- Plumbing: Corrosion-resistant brass fittings, valves, and connectors for long-lasting service.

- Construction: Decorative brass fixtures and functional components for HVAC systems.

- Home Appliances: Durable and aesthetically pleasing parts for kitchen fixtures, lighting, and more.

Why Choose Ruixi Technology for Brass CNC Machining?

At Ruixi Technology, we combine years of experience with cutting-edge CNC technology to deliver precision brass parts with unmatched quality and efficiency. Our facilities are ISO-certified, and we use automated testing to ensure every part meets stringent quality standards. Whether you need rapid prototype machining or high-volume production machining, we have the expertise and technology to bring your project to life.

Contact us today to discuss your next brass CNC machining project and get a free quote!

|

Project Type |

Turnaround Time |

|---|---|

|

Urgent High-Precision Sample |

Within 24 hours |

|

New Mold Requirement |

Mold production in 5 days, sample delivery within 7 days |

|

Standard Prototyping |

Typically 5-7 days |

|

High-Volume Production |

2-4 weeks, depending on project complexity |

Flexible Turnaround Times

At Ruixi Technology, we understand that deadlines are critical. That’s why we offer flexible turnaround times to meet your project needs:

Ruixi Technology Factory

Contact Us for a Vlsit

Brass’s excellent machinability allows for achieving tight precision CNC machining tolerances and exceptional surface finishes.

Standard Tolerances for Brass CNC Machined Par

|

Feature |

Standard Tolerance |

Precision Tolerance |

|---|---|---|

|

External Dimensions |

±0.1mm (±0.004″) |

±0.025mm (±0.001″) |

|

Internal Dimensions |

±0.12mm (±0.005″) |

±0.05mm (±0.002″) |

|

Hole Diameters |

±0.08mm (±0.003″) |

±0.025mm (±0.001″) |

|

Flatness |

0.1mm per 100mm |

0.05mm per 100mm |

|

Surface Roughness |

Ra 3.2μm |

Ra 0.8μm |

Our advanced CNC equipment and quality control systems ensure consistent precision across both small batch CNC machining and high-volume production machining runs.

Certificate

CNC Machining Brass Components- FAQS

Which Industries are CNC Machining Personalized Brass Components appropriate for?

Brass cnc machined components are typically utilized in electrical power, residence devices, construction, vehicle market, industrial equipments, and also the excellent look makes brass components incredibly popular in home accessories.

What Are the Typical Surface Area Treatments of CNC Machining Copper Parts?

Due to the influence of the atmosphere, the surface of brass components will be oxidized to various levels, so various surface area treatment procedures require to be utilized.

Commonly used brass parts surface treatment procedures are as adheres to:

1) Bright cleansing of brass parts

2) Passivation of brass components

3) Anodizing of brass parts

4) CNC machining brass components for electroplating (zinc, nickel, chrome) treatment

5) Chemical sprucing up of copper parts

What Are the Size Limitations for Brass CNC Machined Parts?

Our CNC machining capabilities allow us to produce brass parts ranging from very small components (minimum feature size of approximately 0.5mm) up to large parts measuring 500mm × 500mm × 500mm. For larger parts, we can employ multiple setups or alternative manufacturing methods. Minimum wall thickness for brass parts is typically 0.5mm, though for structural integrity we recommend 0.8mm or greater depending on the specific design requirements.

How Does the Cost of Brass CNC Machining Compare to Other Materials?

While raw brass material costs are typically higher than aluminum (approximately 20-30% more), the total machining cost is often comparable due to brass’s excellent machinability. Brass allows for faster cutting speeds, longer tool life, and frequently requires fewer operations to achieve the desired finish. For high-volume production, the material cost difference becomes more significant, but this can be offset by brass’s superior durability and corrosion resistance, potentially reducing lifetime costs for the end product.

What Are Common Challenges When Machining Brass and How Do You Address Them?

The primary challenges in brass CNC machining include:Lead content regulations: We offer both leaded (C360) brass for maximum machinability and lead-free alternatives (C69300) for applications subject to environmental regulations. Chip control: Brass produces long, stringy chips that can wrap around tooling. We use specialized chip breakers and programming techniques to manage chip formation. Surface finish consistency: Achieving uniform appearance across multiple production runs can be challenging. Our standardized processes and quality control ensure consistency. Tool selection: Despite brass’s good machinability, tool geometry must be optimized. We use specialized tooling with appropriate rake angles for brass machining.

What Quality Control Measures Do You Implement for Brass Components?

Our quality control process for brass components includes:

- First article inspection with detailed dimensional verification

- In-process sampling at defined intervals

- CMM (Coordinate Measuring Machine) verification for complex geometries

- Surface finish measurement and visual inspection

- Material certification verification

- Functional testing when applicable

- Final inspection with detailed reporting

All inspections are documented and performed according to our ISO 9001:2015 quality management system.

What's the Difference Between Regular and Free-Machining Brass?

Regular brass typically contains 60-70% copper and 30-40% zinc without additional elements. Free-machining brass, such as C360, contains approximately 3% lead which significantly improves machinability by acting as a chip breaker and lubricant during cutting. The lead content reduces tool wear, allows higher cutting speeds, and produces better surface finishes.

For applications where lead content is restricted (such as potable water systems or certain consumer products), we offer lead-free alternatives like C69300 (ECO BRASS) which achieve good machinability through alternative alloying elements such as silicon and phosphorus.

What Design Considerations Are Important for Brass CNC Machined Parts?

When designing brass parts for CNC machining, consider:

- Thread design: Brass excels in threaded applications; UNC or UNF threads are preferable to metric threads for optimal strength.

- Corner radii: Design internal corners with minimum 0.8mm radius to accommodate standard tooling.

- Thermal expansion: Brass has a thermal expansion coefficient of approximately 20 μm/m·°C, which should be considered for tight-tolerance applications.

- Wall thickness variations: Maintain consistent wall thickness where possible to prevent distortion.

- Draft angles: Though not required, 1-2° draft angles on deep pockets can improve tool access and surface finish.

- Deep hole limitations: For holes deeper than 5× diameter, consider using special tooling or alternative manufacturing methods.

CNC MACHINING SERVICES

CNC MACHINING SERVICES