Top 10 CNC Machining Companies in UAE Right Now

October 28, 2025

Contents

Key Takeaways

What Makes the UAE a Growing Hub for CNC Machining?

...

We are ready to answer right now! Sign up for a free consultation.

I consent to the processing of personal data and agree with the user agreement and privacy policy

We are ready to answer right now! Sign up for a free consultation.

I consent to the processing of personal data and agree with the user agreement and privacy policy

Die casting turns molten metal into complex, precisely shaped components

through high-pressure injection into reusable steel molds. Ruixi Technology offers comprehensive metal casting services that cover both hot and cold chamber techniques for automotive, aerospace, electronics, and consumer appliance manufacturers. The custom die casting capabilities consistently deliver

tight-tolerance components with exceptional surface quality, providing a

cost-effective solution for high-volume production runs that other

manufacturing methods simply can’t match.

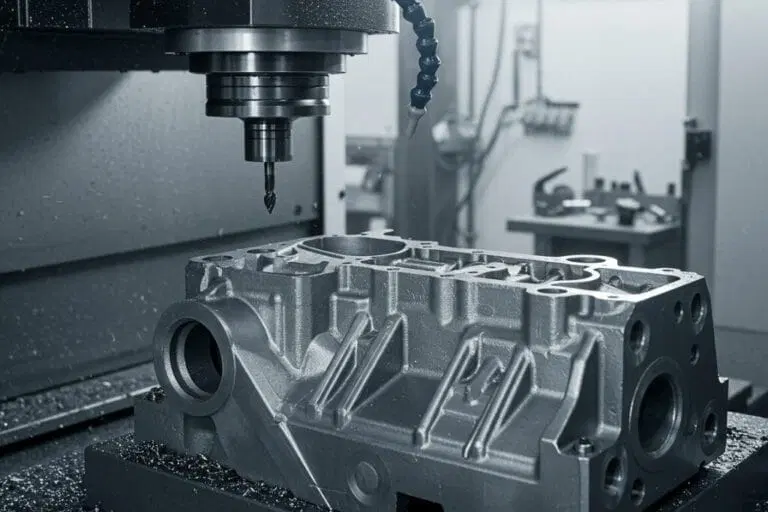

Die casting is pretty fascinating when you break it down — it’s all about forcing molten metal into these specially engineered steel molds under serious pressure. Unlike other manufacturing methods, this technique creates parts with amazing dimensional accuracy, surface finish that often needs no additional work, and mechanical properties that stand up to real-world abuse.

The whole process really comes alive when that molten metal gets shot into the die cavity.

Ruixi Technology handles the entire die casting journey — from initial design concepts all the way to finished, ready-to-ship components. The precision die manufacturing capabilities include some seriously high-precision tooling and advanced quality control systems that catch issues before they become problems. Years of experience working with aluminum and zinc die casting alloys (380, 360, 390, 413, the whole Zamak series) and various magnesium materials have led to expertise in producing components with walls as thin as 0.5 mm — about the thickness of a heavy business card.

Die casting materials include aluminum and zinc alloys with specific properties suited for different applications. Aluminum die casting alloys (380, 360, 390, 413) offer excellent corrosion resistance, high strength-to-weight ratio, good thermal conductivity, and EMI/RFI shielding. Zinc and aluminum die cast components provide superior surface finish, excellent castability for thin walls, and good mechanical properties.

Ruixi Technology ensures casting quality through comprehensive inspection protocols and strict adherence to international standards. Our quality assurance system includes material verification, real-time monitoring, dimensional inspection, and mechanical testing. We maintain ISO 9001 and ISO 14001 certifications while following industry standards from certified die casting organizations.

Design considerations for die casting include wall thickness uniformity, appropriate draft angles, and proper radius placement for optimal metal injection. Wall thickness should remain uniform, typically 0.5-6 mm for zinc and 1.0-10 mm for aluminum, to prevent solidification issues. Draft angles of 1-3° are essential for proper ejection from the die casting mold.

Ruixi Technology offers comprehensive secondary operations for metal die castings. Our in-house precision machining adds features including holes, threads, and complex geometries with tolerances as tight as ±0.02 mm. Surface treatments for aluminum or zinc castings include deburring, polishing, sandblasting, anodizing, powder coating, and chromating.

Ruixi Technology delivers premier die casting solutions through technical expertise, quality focus, and comprehensive capabilities. As a leading die casting co, we combine experience with advanced technologies to produce high-precision metal components that meet demanding specifications. Our integrated approach from design to finishing simplifies your die casting needs while ensuring quality throughout the manufacturing process.

Lorem ipsum, or lipsum as it is sometimes known, is dummy text used in laying out print, graphic or web designs.

Lorem ipsum, or lipsum as it is sometimes known, is dummy text used in laying out print, graphic or web designs.

Lorem ipsum, or lipsum as it is sometimes known, is dummy text used in laying out print, graphic or web designs.

Lorem ipsum, or lipsum as it is sometimes known, is dummy text used in laying out print, graphic or web designs.

A significant disadvantage of die casting is the high initial tooling cost compared to other casting methods. Die casting machines ranging from 250 to 3000 tons require specialized steel alloys and precision manufacturing, resulting in substantial upfront investment ranging from $10,000 to $100,000+ depending on complexity. These makes die casting economically viable primarily for medium to high production volumes where tooling cost can be amortized across thousands of components.

Die casting is not easy but rather a complex manufacturing process requiring specialized expertise, equipment, and technical knowledge. The process demands precise control of numerous variables including temperature, forces of molten metal under pressure, and cooling rates. Engineers must understand metallurgy, fluid dynamics, thermodynamics, and mechanical design to create successful die casting tools and processes. Producing quality components consistently requires sophisticated equipment, rigorous controls, and experienced operators.

Free Machined Parts Design to Your Projects with Fast Turnaround Times.