Top 10 CNC Machining Companies in UAE Right Now

October 28, 2025

Contents

Key Takeaways

What Makes the UAE a Growing Hub for CNC Machining?

...

We are ready to answer right now! Sign up for a free consultation.

I consent to the processing of personal data and agree with the user agreement and privacy policy

We are ready to answer right now! Sign up for a free consultation.

I consent to the processing of personal data and agree with the user agreement and privacy policy

Ruixi Technology offers precision CNC Turning Service China with

tight tolerances and exceptional accuracy. Parts can be finished in as fast as one

day with no minimum order, whether you need prototypes, small-batch

production, or high-volume manufacturing, all at competitive prices.

CNC Turning Part Cases & Product Gallery

Our state-of-the-art CNC turning capabilities include:

CNC turning can be carried out in a variety of materials, including different metals and plastics. Our optimal material selection for CNC turned components ensures the best performance for your specific application:

MetalsWe offer a comprehensive range of surface treatments to enhance both aesthetics and performance:

You will receive a quick quotation in 3-5 hours on work days after sending your design file with detailed specifications, sizes, and quantities. 24/7 support all year round.

You rest assured to get high-quality CNC milling parts as desired with our careful drawing checks and strict quality inspections.

Choose from over 30 kinds of metal and plastic materials. Ruixi Technology offers a wide variety of certified materials for your custom milling parts.

You will receive a quick quotation in 3-5 hours on work days after sending your design file with detailed specifications, sizes, and quantities. 24/7 support all year round.

Your ordered parts can be finished as fast as one day and shipped to you right away. Ruixi Technology features advanced technologies to accelerate production.

No minimum order quantity is required. One-piece prototypes, low-volume manufacturing or mass production at the most competitive price.

Optimizing your design for CNC turning can significantly reduce costs and improve quality:

Our engineering team provides free design to optimize your parts for manufacturability and cost-effectiveness.

At Ruixi Technology, quality is built into every step of our manufacturing process:

There is a wide selection of materials with various specifications to produce your CNC machining parts.

The quotation of the custom CNC parts will differ depending on the different materials used.

Many companies outsource CNC turning to China, and Ruixi Technology stands out as a premier partner in this endeavor. As a leading provider of CNC machining services, we combine quality, efficiency, and cost-effectiveness to meet the needs of clients worldwide, especially in the USA.

Here’s why Ruixi Technology is the right choice:

At Ruixi Technology, we utilize state-of-the-art CNC turning machines equipped with advanced technology to ensure that every part we produce meets the highest standards of precision and quality. Our rigorous quality control processes guarantee that each component is manufactured to exact specifications, which is crucial for our clients in industries where precision is non-negotiable.

Outsourcing your CNC turning needs toRuixi Technology allows you to significantly reduce manufacturing costs without sacrificing quality. Our competitive pricing structure is designed to provide maximum value, making us an attractive option for businesses looking to optimize their production budgets. The lower labor costs in China, combined with our efficient manufacturing processes, enable us to offer rates that are difficult to match.

In today’s fast-paced market, speed is essential. We understand the urgency of your projects and are committed to delivering your CNC turned parts quickly and efficiently. Our streamlined processes and experienced team allow us to meet tight deadlines, ensuring that you receive your components when you need them.

Ruixi Technology works with a wide range of materials, including metals, plastics, and composites. This versatility allows us to cater to various industries, from automotive to aerospace, ensuring that we can meet the specific needs of our clients in the USA and beyond.

With years of experience in the CNC machining industry, our skilled engineers and technicians possess the expertise necessary to handle complex CNC turning projects. We leverage our knowledge to provide innovative solutions that enhance the performance and functionality of your products.

We recognize that every project is unique. Our team collaborates closely with you to understand your specific requirements and develop tailored solutions that align with your goals. Whether you need a one-off prototype or a large production run, we are here to support you every step of the way.

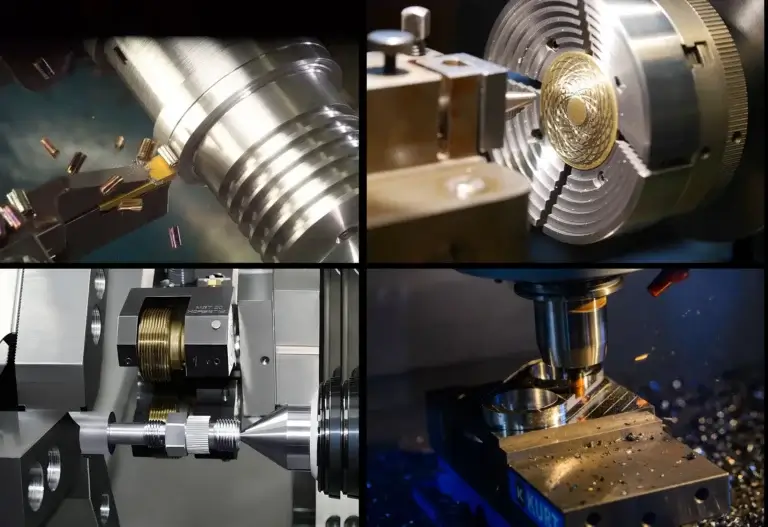

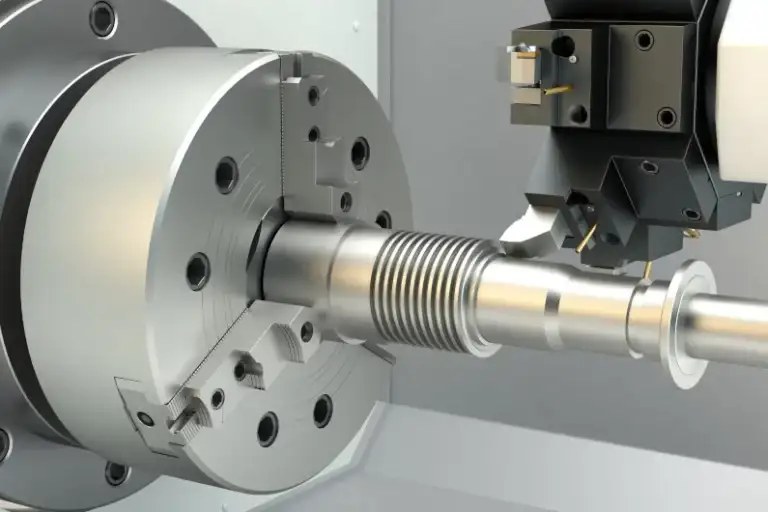

CNC turning is a specialized type of CNC machining process focused on material removal. In this process, workpieces are securely held in a chuck and rotated at high speeds. A turning cutter is then fed into the rotating workpiece, effectively cutting away material until the desired custom CNC-turned parts are achieved.

This method operates on the same fundamental principles as traditional lathe machining, making CNC turning one of the oldest manufacturing techniques still in use today. However, with the integration of computer numeric control (CNC), it offers enhanced precision and efficiency.

In CNC turning services, the feed rate is typically measured in inches per revolution (ipr) or millimeters per revolution (mpr), allowing for precise control over the machining process.

CNC turning is particularly well-suited for producing cylindrical-shaped workpieces, such as shafts, disks, and sleeves. It can also accommodate non-cylindrical shapes, including square or hexagonal parts, making it a versatile option in modern manufacturing.

Our online CNC machining services cater to various industries, including automotive, aerospace, medical devices, electronics, and consumer goods.

For a general idea of CNC turning costs typically cost around $8-$16 per hour to operate. To get a precise estimate tailored to your project requirements, feel free to request a quote.

With improved technologies and extensive expertise in CNC machining, Ruixi Technology produces high-quality and cost-effective metal/plastic custom CNC turned components with high precision guaranteed for your innovative projects.

While capable of processing square and hexagonal-shaped materials, the CNC turning process is best for tubular and circular shaped raw materials, including the following:

Modern CNC turning machines are capable of handling different tools, spindles, and speeds. With various cutting tools available, CNC turning machines can create different parts with complex geometries. Generally, CNC turning is popular for making parts with the following criteria:

Overall, CNC turned parts are widely used in the field of machine manufacturing, aerospace, automobile part manufacturing, and service factories.

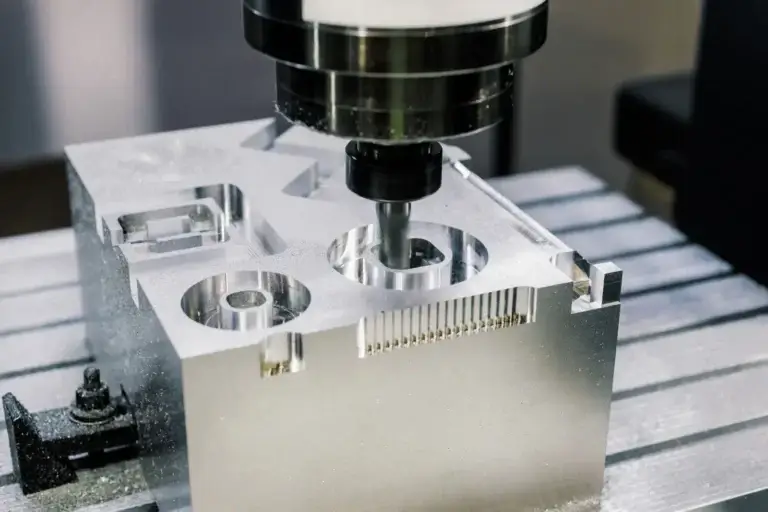

In contrast, CNC Milling utilizes rotating cutting tools that move against the stationary workpiece. This process is versatile and can create a wide range of shapes, including flat surfaces, complex contours, and intricate designs. CNC milling is particularly effective for machining irregular and flat surfaces, making it suitable for parts that require detailed features and precision. If you’re looking for more complex machining solutions, you can opt for CNC milling China, which is ideal for creating intricate designs and precision parts with rotating cutting tools.

A CNC lathe specializes in turning operations, efficiently producing cylindrical parts through processes like turning, facing, and threading. In contrast, a CNC turning center is an advanced machine that expands on the capabilities of a CNC lathe. In addition to facing, threading, and knurling, it can perform drilling, boring, reaming for precise holes, and even milling to create complex shapes.

In CNC turning, the most common configuration involves two primary axes:

Z-axis: This axis represents the spindle’s rotation and is aligned with the length of the workpiece. It allows for longitudinal movement along the length of the part being machined.

X-axis: This axis is perpendicular to the Z-axis and allows for radial movement, enabling the cutting tool to move in and out from the center of the workpiece to adjust the diameter.

The Top 10 China CNC Turning Parts Manufacturers are recognized for their expertise, precision, and reliability in producing high-quality CNC turning parts for various industries. Among these, Ruixi Technology stands out as a preferred choice for its commitment to excellence and customer satisfaction. For the full list and detailed insights, visit our guide here: Top 10 China CNC Turning Parts Manufacturers.

Free Machined Parts Design to Your Projects with Fast Turnaround Times.